Dual-mode MRS Sensor works with Automatic Optical Inspection and Coordinate Measuring Machines for Solder Paste Inspection

CyberOptics has developed a Dual-Mode MRS sensor for dedicated solder paste inspection with one mode for high speed and another for high resolution inspection. The sensor is based on the Multi-Reflection Suppression device for semiconductor and SMT markets. It is ideal for measuring height, area and volume as well as registration and bridging.

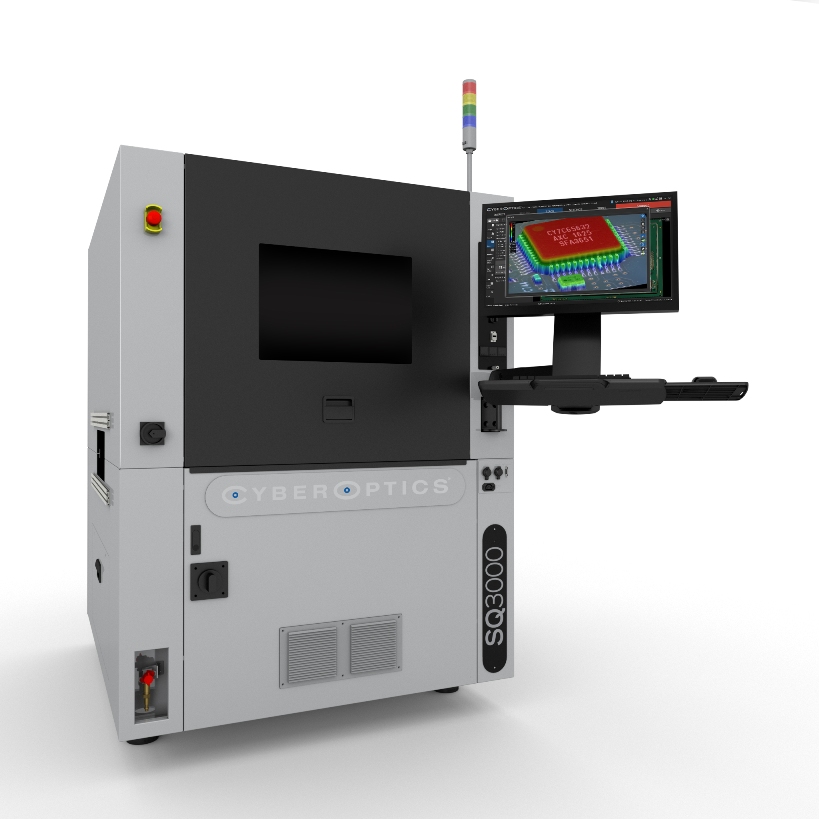

CyberOptics has also been demonstrating its SQ3000+ Multi-Function system for inspection and metrology, an extension of the SQ3000 platform that not only conducts AOI and SPI, but also delivers in-line, full coordinate measurement (CMM) data in seconds, not hours. The system offers high accuracy and high speed, with an even higher resolution MRS sensor that inhibits reflection-based distortions caused by shiny components and surfaces.

The SQ3000+ is designed for high-end applications including advanced packaging, mini-LED, advanced SMT for medical, military, aerospace and advanced electronics, 008004/0201 SPI, socket metrology and other challenging CMM applications.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020