The growth in popularity of collaborative robots is driving innovation and increases in capacity

The use of automation in manufacturing, testing and distribution is continuing to gather significant pace, some of which is as a result of the trend towards using cobots (collaborative robots) on tasks that require some human input.

One area where collaborative robotics is gaining ground is in welding and fabrication with one supplier, Universal Robots, having grown its welding application segment by more than 80% in this year alone as partners are developing new capabilities for the company’s new range of cobot welders.

Welding Cobots

Previously dismissed as too heavy-duty a task for cobots, welding is now the fastest growing application segment for Universal Robots (UR) with the company expecting to ship well over 1,200 welding cobots this year.

Since the first UR cobot-powered welder made its debut in 2017, a number of companies now standardise their machinery on the basis of UR products, including Vectis Automation with its Park’N’Arc welder, which has a rotational range extender that allows for the base of the cobot to be manually moved to various locations. Compared to a short linear track, the Park’N’Arc is an improved design for increasing range as the cobot base can be translated nearly 3m in a linear direction while maintaining simplicity, robust cable management and portability.

A similar approach to providing flexibility to welding equipment operators is the RT1 cobot-controlled rotary table from Hirebotics and Kinetic Technologies, which is designed to maximise welding capacity by giving users the ability to rotate the part to the front and back for welding. It also gives users with high volume production requirements the ability to have separate load and weld stations; loading a part on one side while the cobot is welding on the other, increasing arc on time and throughput.

Bin Picking and Machine Tending

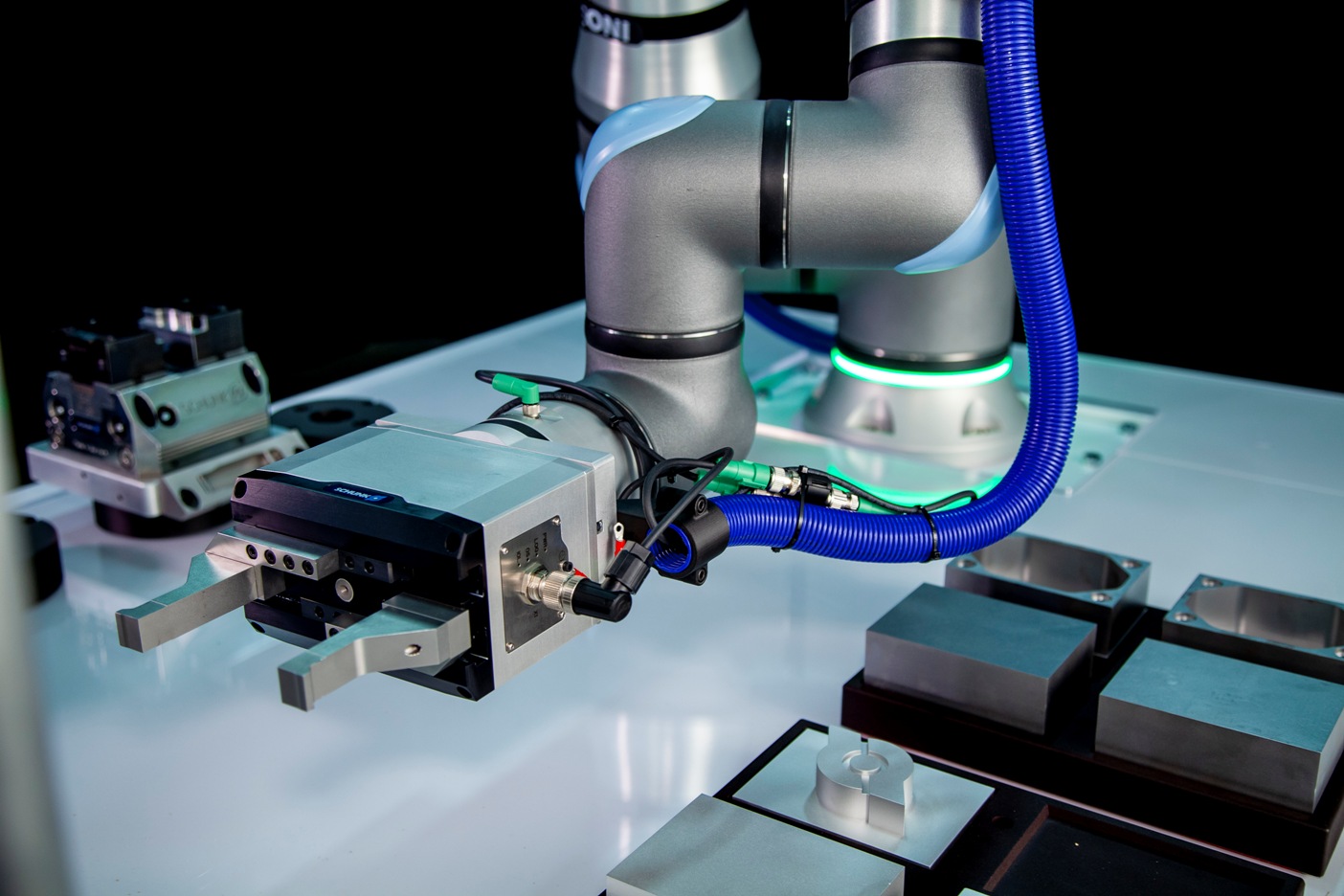

Picking unstructured parts out of bins is another traditionally challenging task to automate, something which Precision Cobotics has solved with a UR5 cobot, which is able to pick a shiny metal part from a randomised bin and place it into a laser marking machine. The UR5 is guided by Apera AI’s new UR+ certified Vue Vision software that accurately locates and places the part.

According to Eric Petz, head of marketing at Apera, robotic bin picking systems often struggle with shiny or complex objects and usually have much longer cycle times than a human performing the same actions.

“The Vue Vision software provides the industry’s fastest total vision cycle time, as low as 0.3 seconds, and operates under ambient light using standard cameras, so the user does not need expensive specialist equipment,” he says.

Universal Robotics has also recently introduced a new 20kg payload cobot, the UR20, which greatly expands automation opportunities such as the ability to reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts than other UR cobot models. Despite being UR’s most powerful robot, the UR20 is the lightest cobot in its class, weighing only 64kg.

“We are also launching a redefined cobot that has been completely re-engineered from the ground up, focused on freeing up more manpower within a wide range of human-scale automation tasks,” concludes Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots.

Capacity Expansion

The cobot market is so promising that American robotics and automation specialist company, FANUC has recently started construction of its new 800,000+ square foot West Campus facility in Auburn Hills, Michigan.

At the ground breaking ceremony that was held last month, a FANUC CRX Cobot, built to work alongside people, was on hand to assist company executives and a group of VIPs to break the ground for the new facility.

With the addition of the West Campus facility, FANUC America will occupy nearly two million square feet of operational space in Oakland County, Michigan.

According to Mike Cicco, President and CEO, FANUC America, The investment in new facilities represents the company’s commitment to the future of US manufacturing using the latest technology available.

“Since opening our 460,000 square foot North Campus three years ago, our business has increased significantly, and further expansion enables us to help more customers – large and small – achieve their production goals.”

The company is also planning to enlarge its training facilities to cope with the additional demand that its cobot output will create. Therefore, FANUC is moving its customer training academy to the same location as the new factory once the commissioning work is complete, making it the largest corporate automation training operation in the USA. The redesigned facility will include more classrooms to provide better learner-to-instructor interactions, as well as increased lab space for hands-on training.

Cicco went on to say that a recent Deloitte study found that there will be at least two million unfilled manufacturing jobs within the next eight years and that’s why automation is growing at such a rapid pace.

“Our new Training Academy underscores FANUC’s commitment to helping companies upskill their employees and keep production running smoothly. This in turn will enable workers to enhance their career growth opportunities as they learn how to operate robotic and automation equipment,” he concludes.

FANUC’s products are applied in a wide range of industries including automotive and EV, aerospace, consumer goods, pharmaceuticals, logistics and warehousing. The new West Campus is scheduled to open in the spring of 2024.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020