Open access UK battery manufacturing facility makes use of advanced robotics

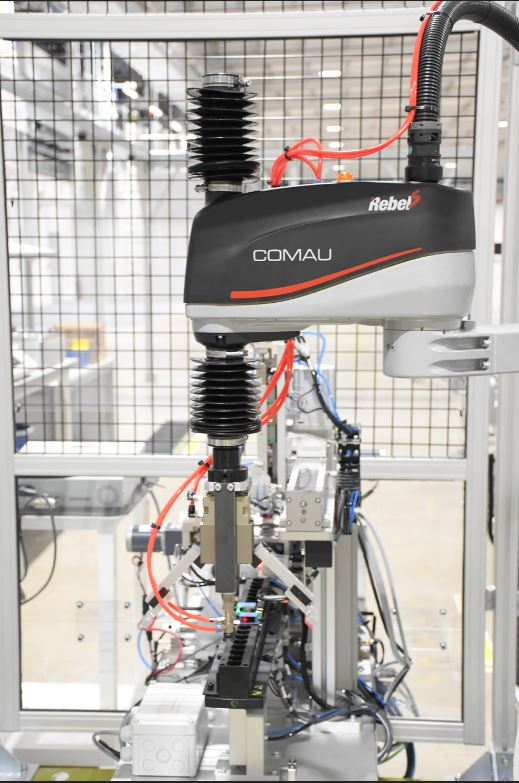

Comau UK has been selected by the UK Battery Industrialisation Centre (UKBIC) to develop and deploy a semi-automated battery module and battery pack assembly line for the publicly-funded ‘open access’ battery production development facility.

The Module and Pack assembly line is the first of UKBIC’s innovative battery manufacturing equipment to have been installed, commissioned and available for its customers to use.

One of the unique elements of the project was the requirement for agile flexibility, which will allow UKBIC to manufacture a wide range of Modules & Packs, and support various customer requirements without the need for major process or site changes.

Working in collaboration with engineers from UKBIC, Comau UK provided all the necessary technology and know-how to manage the entire battery Module & Pack manufacturing process, from cylindrical cell preparation and pouch cell stacking to the battery pack assembly. The facility is located in Coventry, about 30 miles southeast of Birmingham and 20 miles from the Comau UK facilities in Rugby.

Proving ground for battery manufacturers

To meet the demand for UK-produced batteries, which is expected to reach a total of 440 gigawatt-hours per year by 2040, the 18,500 m2 UKBIC facility with its Comau-developed Module and Pack manufacturing line will allow British companies to determine whether their prototype technology can be manufactured at the required volume, speed, performance and cost to be commercially successful.

In addition to helping ensure the safety and reliability of the manufactured batteries through the use of smart cameras, thermal imaging and End-of-Line leak test technologies, the system has built-in scalability to handle greater production volumes when required. Furthermore, thanks to its facility in the in UK, Comau offers the added value of delivering a seamless, barrier-free, intra-continental customer experience throughout every step of the electrification process – from proposal to engineering to execution.

Commenting on his company’s selection as the main technology partner by UKBIC for its Module and Pack assembly line, John Coombes, Managing Director of Comau UK believes the combination of Comau’s collaboration with the customer and their dynamic resolve to adopting technology has proven to be a winning approach for both companies.

“More importantly, the cutting-edge facility will allow UKBIC to remove barriers that would otherwise slow the development of these promising new technologies,” he says.

Ian Whiting, UKBIC’s Commercial Director, added: “We’re delighted to have our Module and Pack line up and running at UKBIC, the first part of the facility which customers can use. From the outset, the team at Comau have helped us realise our goal of proving whether promising technologies can be manufactured at the required volume, speed, performance and cost to be commercially successful.”

UKBIC is an important part of the UK’s Faraday Battery Challenge programme, which is designed to fast track the development of cost-effective, high-performance, durable, safe and recyclable batteries.

As well as Module and Pack capability, the battery manufacturing equipment being installed at the facility covers the whole production process from electrode manufacturing, cylindrical and pouch cell assembly, to formation aging and testing, as well as a prototyping competence centre for specialist ultra-low volume builds. The plant is a pioneering facility, which provides the missing link between battery technology, which has proved promising at laboratory or prototype scale, and successful mass production.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020