Chinese rolling mill undertakes condition monitoring and vibration analysis to extend the life of its board mill equipment

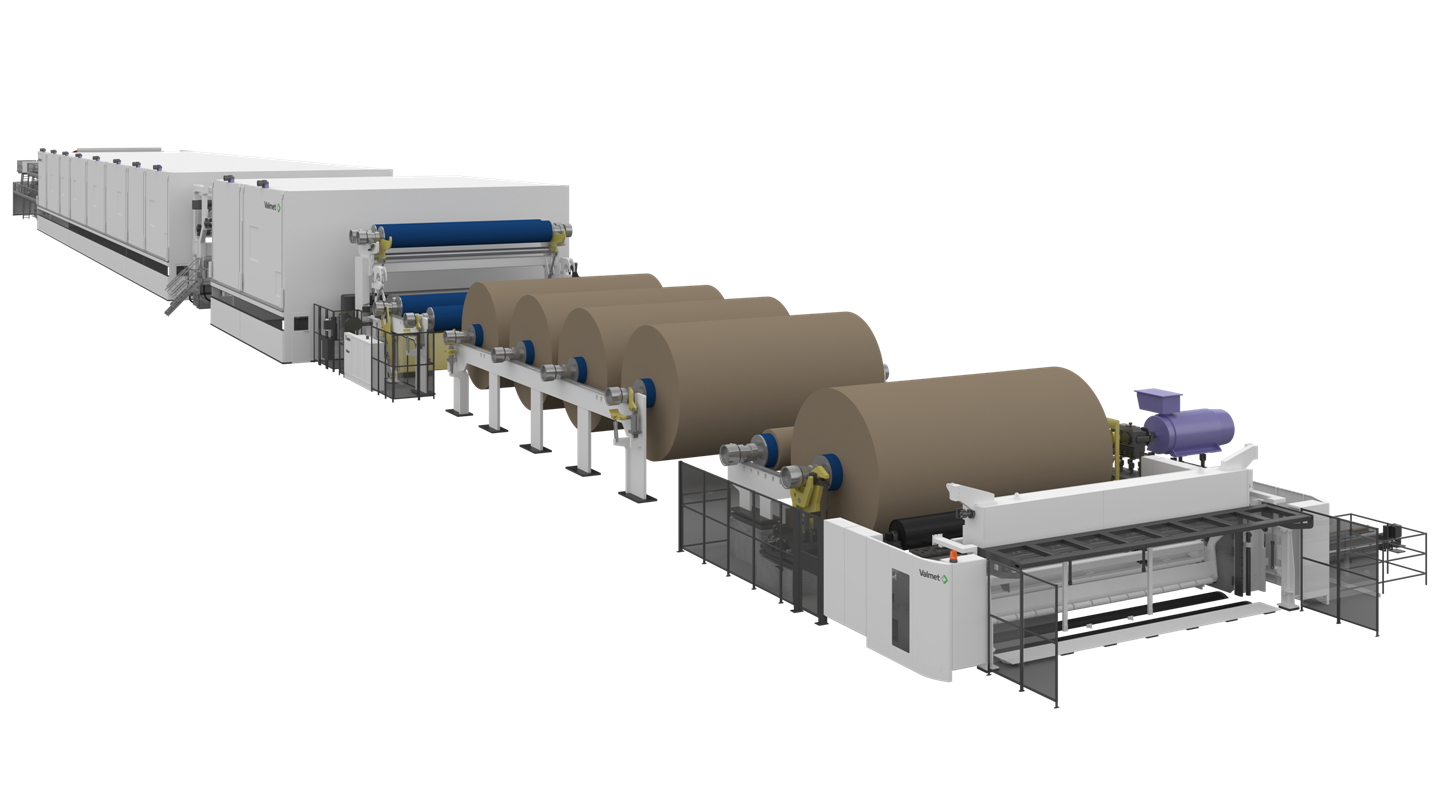

Finnish heavy process machinery specialist Valmet will provide roll maintenance and condition monitoring services to Shanying International at the company’s Anhui mill in China.

The services cover roll grinding, recovering and reconditioning, roll condition monitoring and vibration analysis for five board machines together with on-site investigation and Valmet Industrial Internet remote analysis and diagnosis.

Using the condition monitoring services, Shanying expects to see increased roll lifetimes with significant reductions in unplanned downtime and roll regrinding.

“The extensive mill personnel training that’s been undertaken supported by our vibration experts via a secure data connection makes full use of the mill’s roll condition monitoring systems. The service agreement will ensure a high level of equipment maintenance and management,” says Shiming Xu of Valmet China.

DNA Machine Monitoring collates machine and roll condition information for process operators and maintenance personnel through one common user interface. Operators are immediately alerted if there is a risk of machine/roll failure and indicators of roll condition, while the paper machines are running, are easily analyzed.

A secure Valmet Industrial Internet remote connection allows Valmet experts to provide an agreed level of remote diagnostic support for machine problems and roll maintenance decisions.