Test house moves to 5-axis CMM capabilities to meeting increased demand for measurement performance

Engineering technology is changing at a pace that is unprecedented in terms of the combined requirement for precision and volume and thus providing a significant challenge to test and measurement service providers.

This step-change in such factors led CMM specialist, Apex Metrology Ltd (Apex), to conduct a strategic review of the services that it offers. Customer demands were changing rapidly and becoming less predictable. Part complexities were increasing, delivery deadlines shortening and production volumes becoming more fluid. Under such circumstances, in order to maintain its service levels in line with customer expectations, the company decided to move to Renishaw’s Revo 5-axis co-ordinate measurement system and Equator gauging system as a method of future-proofing what would be needed for the years ahead.

Metrology Service Provider

Founded in 2003, Apex Metrology’s customer base includes a diverse range of companies from sectors including aerospace, automotive, medical and energy.

The Scottish company offers its customers a comprehensive service that helps keeps pace with on-going developments in CMM technology and international quality standards.

Brian Young, Managing Director of Apex said, “Businesses need to make the most of CMM technology in order to truly benefit from quality control, efficiency savings and product differentiation. To be used to their full potential, CMMs require constant, proactive support.”

Apex’s range of accredited, quality assured CMM services comprises parts inspection and verification, software programming, validation and training, system maintenance, installation, retrofits and upgrades. Apex works with customers throughout Scotland, Northern Ireland and the North of England.

Until now, Apex has always offered its customers the services of an installed base of in-house CMM equipment that included 3-axis CMM systems using traditional touch-trigger and scanning probes mounted on PH10 motorised indexing heads.

Business Challenge

Like any business operating in an international high technology market, Apex is by no means immune to the impact of macro-economic factors.

Young explains, “With advances in product design software, material technologies and metal 3D printing, we began to see a general increase in the different types and volumes of CMM projects we were presented with. This technological evolution, combined then with the Brexit decision and the global COVID-19 pandemic, created a new set of business challenges to address.”

Moves by many businesses to identify more local sources of supply, a need for them to further minimise operating costs and observe restrictions on long distance travel and social distancing for example, meant the profile of the Apex customer base and its needs was changing rapidly.

He continues, “We knew we had to adapt and further augment the service we were offering. Customer planning horizons were also becoming shorter. What were previously quite predictable and cyclical demands became far less assured. It was clear that we needed to become even more agile than we were and to introduce even higher levels of future-proofing.”

To continue to meet its customers’ expectations, Apex made the decision to increase its in-house capabilities with a strategic investment in next-generation metrology equipment.

5-axis CMM

In-depth discussions with Renishaw led to a rigorous review of existing Apex facilities and a formal proposal was made to begin a migration to state-of-the-art 5-axis CMM technology, partnered with the introduction of a high-precision shop-floor gauging system.

Approving Renishaw’s technical recommendations, Apex committed to the immediate retrofit of its existing DEA Global 3-axis CMM using the Reva 5-axis multi-sensor measurement system comprising infinite positioning head, tactile measurement sensors, controller and Renishaw’s own Modus software.

Young says, “The upgrade of one of our 3-axis CMMs made perfect sense, from both technical and commercial perspectives. The cost and lead-time involved in installing a brand new 5-axis CMM was prohibitive and we just knew the existing CMM still had plenty of good service left in it.”

The Revo system incorporates 2 rotary axes in the Revo head as well as the existing 3 linear axes on the CMM frame. The Revo head has its own error map, like the CMM, so that the system knows exactly where the probe tip or sensor is at any time. The result is that you only have to calibrate the probe in one position and then you can use any angle you choose for maximum feature access, saving costly calibration time, reducing set-ups and simplifying programming.

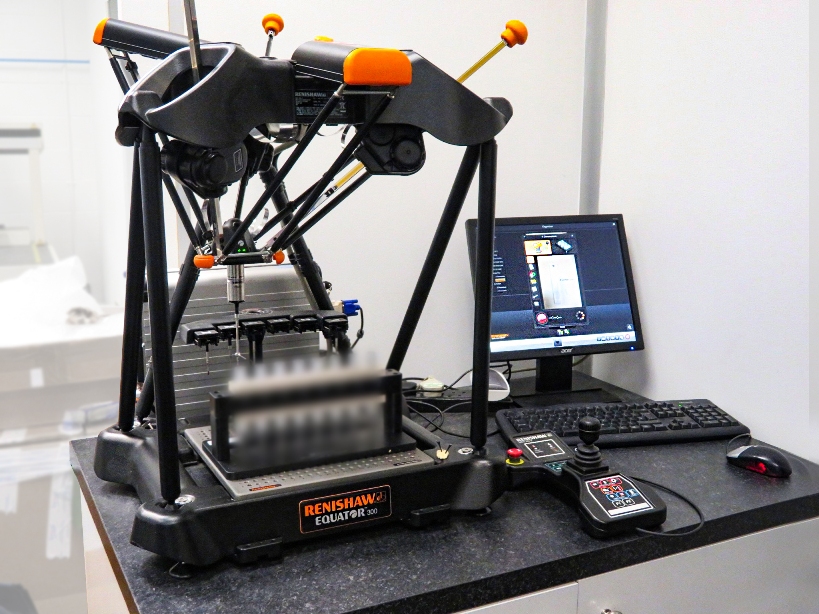

For inspecting medium to high volume manufactured parts, Renishaw’s Equator high-speed comparative gauging system was also added to Apex’s in-house capabilities.

Renishaw’s Equator gauging system is a highly repeatable gauging technology operating on the traditional principle of directly comparing production parts with a reference master part. Remastering is as simple as measuring a production part anew, which automatically compensates for any change in thermal conditions.

According to Young, as with Revo, bringing in the Equator gauging system was another very obvious approach. Creating the sort of sanitised, clean room space required by alternative high-volume gauging equipment just wasn’t going to happen. It needed to suit Apex’s own facility and the varied throughput demands it regularly faces, which the Equator’s flexibility offers.

Installation of the Revo and Equator systems was supported by a blended mix of hardware and software training conducted both online and face-to-face, at the Apex facility and Renishaw’s UK training centre.

Improved Capability

Apex’s additional investment in Revo and the Equator gauging system means it is now able to support a broader customer base and handle the measurement requirements of far more complex parts. Measurement capacity, throughput and productivity have all been increased as a direct result.

At the same time, by extending its natural area of competence to cover 5-axis as well as 3-axis CMM technology, Apex has also been able to augment its customer service offering.

According to Young, Revo 5-axis technology and the Equator gauging system have had a big impact on the business. They have given Apex that extra turnkey capability that it needed to be more responsive in the face of rapidly evolving customer demand. Change is ultimately inevitable, and there was a pressing need to be ready for it.

“It’s not all about high volumes of parts though, customers bring us the more demanding parts to be measured, those with high complexity. We help them reduce their production bottlenecks and provide them with training services that are built on real experience and are not just ‘out-of-the box’,” he says.

Many businesses operating legacy 3-axis CMMs are faced with dilemmas. Older machines are facing technical obsolescence, particularly with the control system and software, yet mechanically they remain perfectly sound. 5-axis retrofitting avoids the need to buy all-new by boosting performance and adding longevity.

Within a short time of introducing its 5-axis CMM and comparative gauging services, Apex had handled a variety of new customer projects, including its first commercial gauging project in the automotive components sector as well as third party Revo software program validation for a major aerospace project.