A new sensor uses fluxgate technology to measure EV charging station current leakage

In the rush to move the world over to electric vehicles and conform to legislation that’s been developed in scores of countries, the requirement for charging infrastructure is growing at a rate that isn’t currently being matched by reality. According to the latest figures from Bloomberg, at the end of 2020, there were just 1.4 million public charging points worldwide, most of which are in China and the EU. In the UK, estimates from EDP Energy put the figure at 35,000 currently in existence in around 13,000 locations.

However, public charging points are just part of the picture with the majority of charging locations being in the EV owners’ own homes or privately owned charges in the workplace.

According to electrical measurement specialist LEM, 2019 saw around 6.5 million private charging points worldwide, not nearly enough to meet the expected growth in ownership. Of course, plugging the car into a mains socket will do the job, albeit slowly and in the least effective way so there is huge pressure on charger manufacturers to supply more effective products to the home market.

LEM believes that to support the massive deployment of EVs, driven by ambitious policies to phase out sales of internal combustion engine (ICE) vehicles, the charging infrastructure must increase by thirteen times.

Meeting the Standard

Due to this, manufacturers must develop chargers that are affordable, easy to install and conform to standards criteria, both for safety and robustness of the product.

Since 2016, IEC standards and more specifically IEC 62955 / IEC 62752, require the detection of a direct leakage current at 6 mA DC to avoid the home Residual Current Device (RCD) Type A being ineffective. This effect, called “the blinding effect”, appears when an EV develops an insulation fault.

EV architecture integrates a battery pack, powered by Direct Current (DC), which can generate a leakage current that can deactivate a home RCD. To protect the RCD and avoid the need to install an RCD type B in the electrical panel of home EV owners, EV chargers include a device to detect the DC leakage current.

Leakage Current Detection

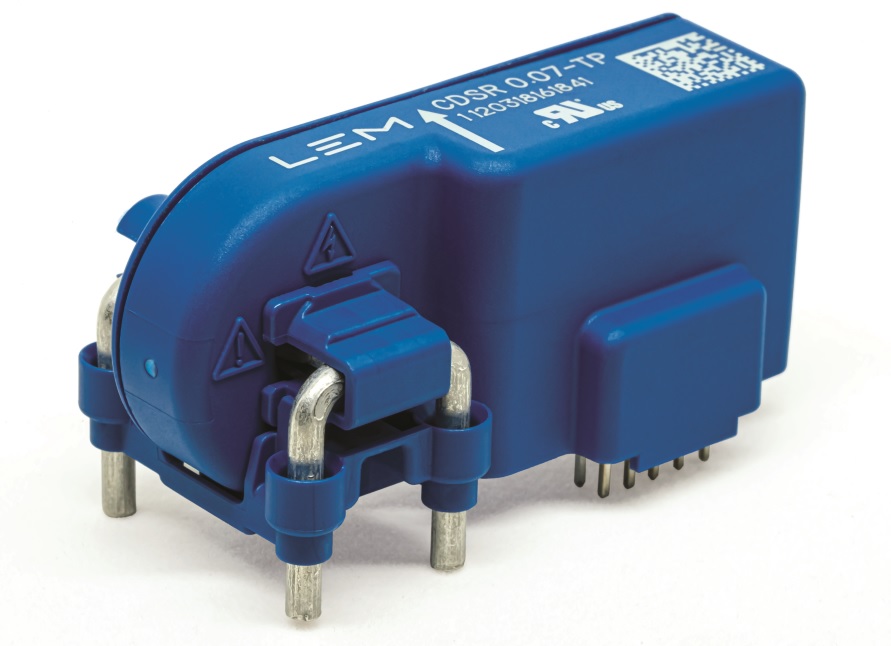

This detection is the role of a new leakage current sensor based on open-loop fluxgate technology. Called the CDSR, the sensor is innovative, extremely compact and safe, allowing manufacturers to optimise the electronic design of their charger products..

The CDSR has been developed to meet market demand for a residential and commercial charging station, offering a version for single-phase architecture and another for three-phase topology. With a maximum current per phase of 32A rms, the CDSR can be integrated into AC chargers from 3.7 kW to 22kW.

Following the trend towards digital electronics, the CDSR provides not only an analogue communication output but also a Serial Peripheral Interface (SPI), enabling simple interfacing of hardware. The CDSR operates from a +3.3VDC supply and has a typical current consumption of just 50 mA when measuring 150 mA as a maximum primary residual current.

The ratio-metric behaviour of the CDSR ensures it can resist power supply drift and maintain astable output measurement.

Extremely robust, the CDSR can operate inside all EV chargers. It has an operating temperature between -40°C to 85°C, can withstand acceleration forces up to 10G while maintaining nominal performance, and has a very high level of insulation between its primary and measurement circuits, thanks to long creepage and clearance distances (13.2 mm).

Designed to ensure a high level of safety, the CDSR provides a default detection output signal with a reaction time below 200µs. Combined with an independent test winding, charger manufacturers can test the performance of the sensor in real time to guarantee maximum safety.